W9 - P3 Progress

What we are making

Our absurd hotel item is an OCD hanger. It enforces all the clothes are facing the same direction before hanging on the rack. The hook will rotate to the same orientation automatically, no matter which hand is holding. When the hanger detects the clothes’ faces in the wrong direction, it turns to a "U" shape hook preventing the user from hanging on the rack.

The hanger consists of three main parts:

A rotational hook

A set of accelerometers recognizing the facing direction

Light sensors detecting the clothes front and back

Prototypes

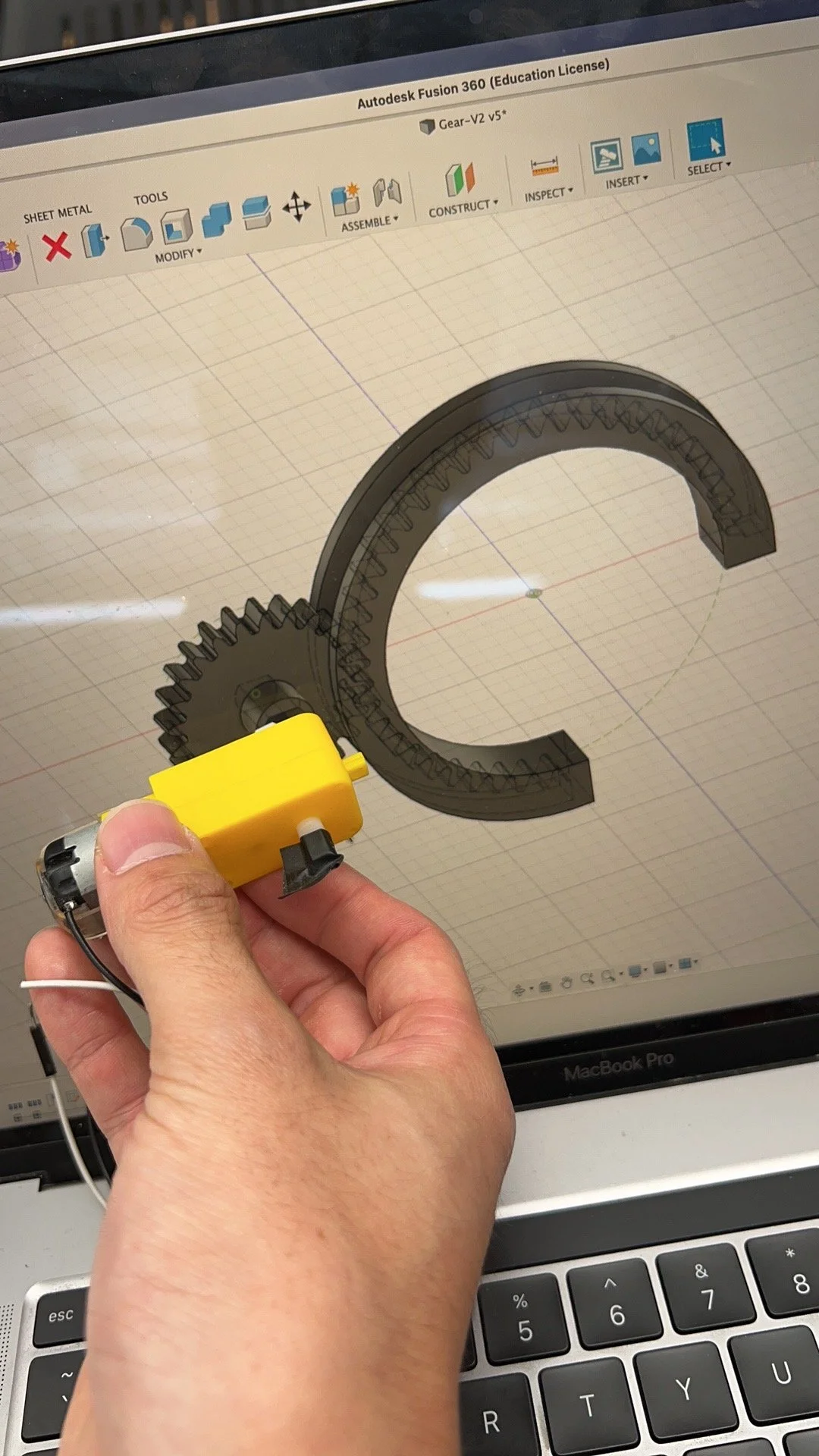

Hook mechanism

From the beginning, we wanted to create a new mechanism for the hook that can be electronically controlled smoothly and elegantly.

We came up with several iterations of the mechanism.

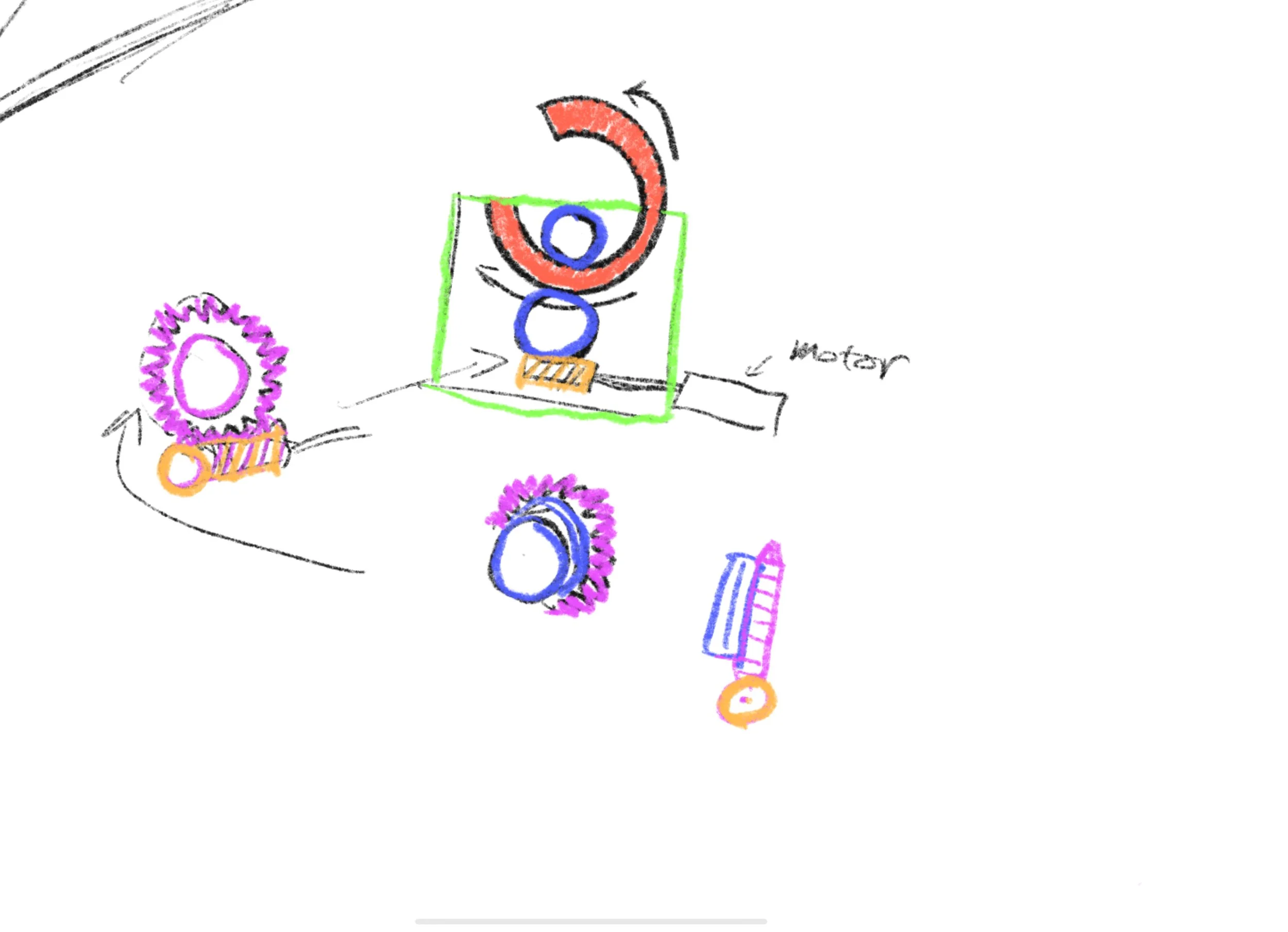

The initial plan was to use two rubber wheels on two sides of the hook by driving the lower wheel with a DC motor with a worm gear.

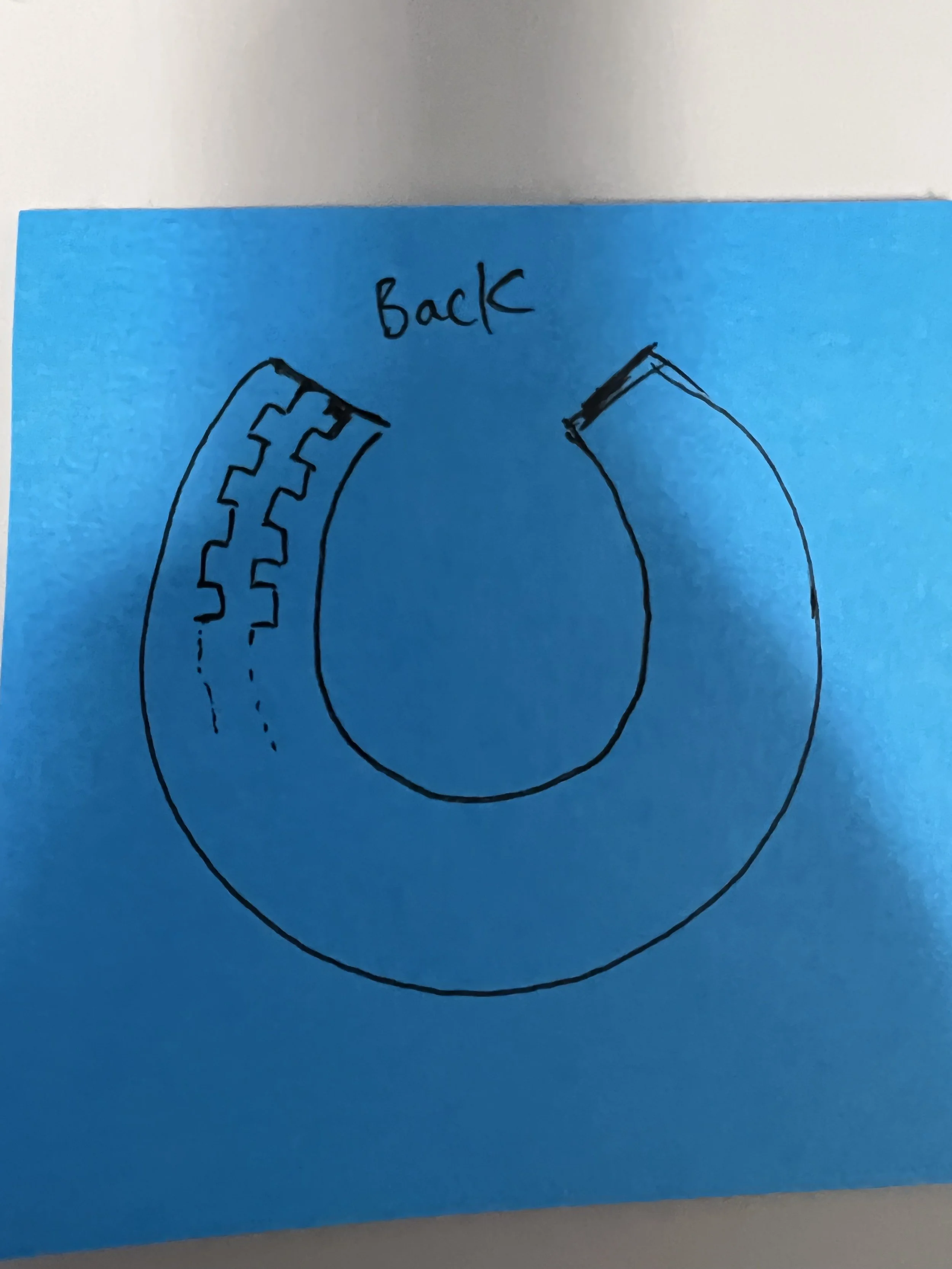

The problem with the first plan was the hook was moving purely by friction. There are high chances of slippering between the two wheels. So we changed wheels into gears and stuck the gears on the back of the hook.

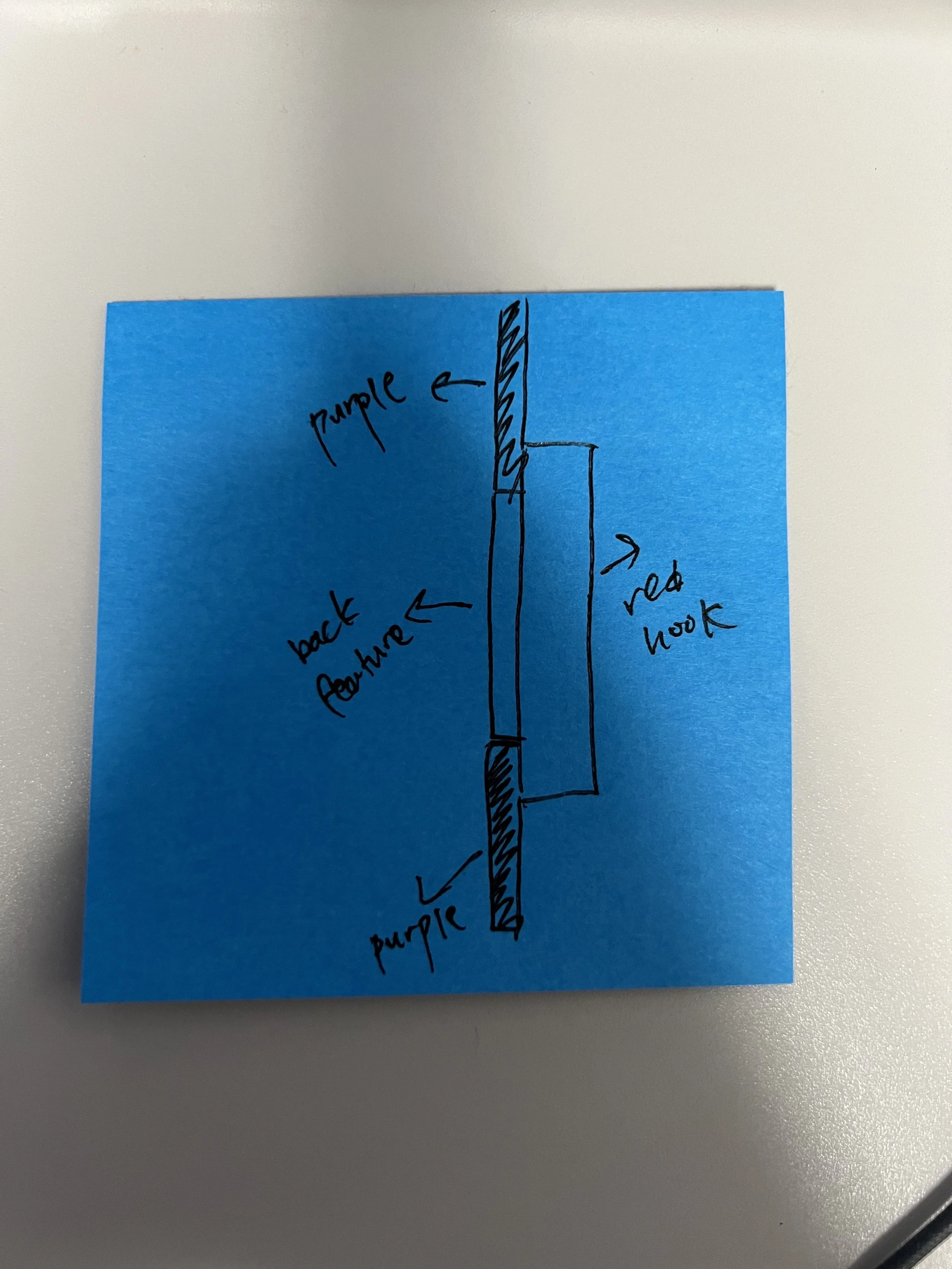

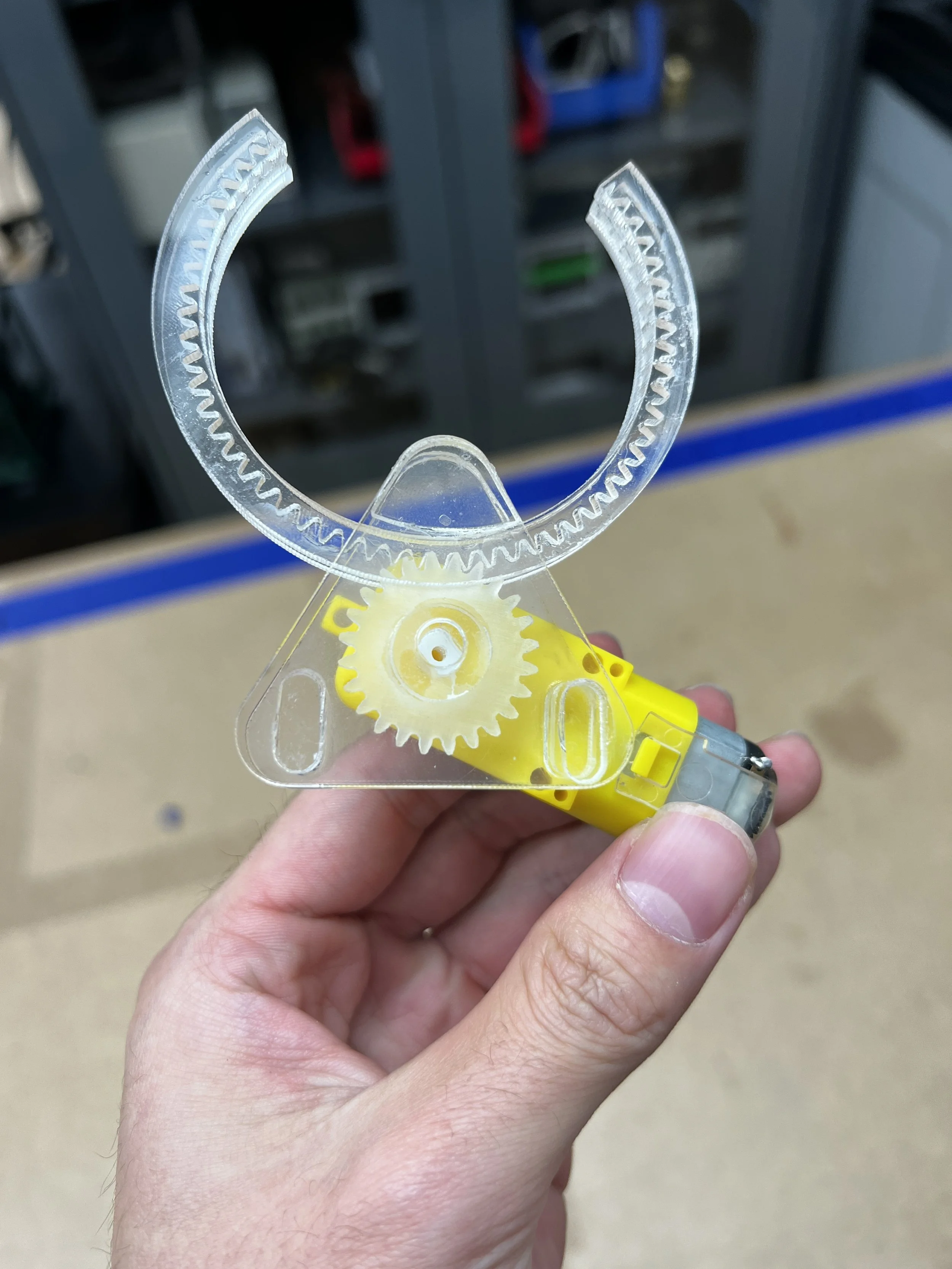

The challenge of the second plan was the number of gears involved in the mechanism, making it hard to calculate the correct combination among four gears. So we landed on the last, also our final iteration. We eliminated the upper gear and integrated the gear inside the hook.

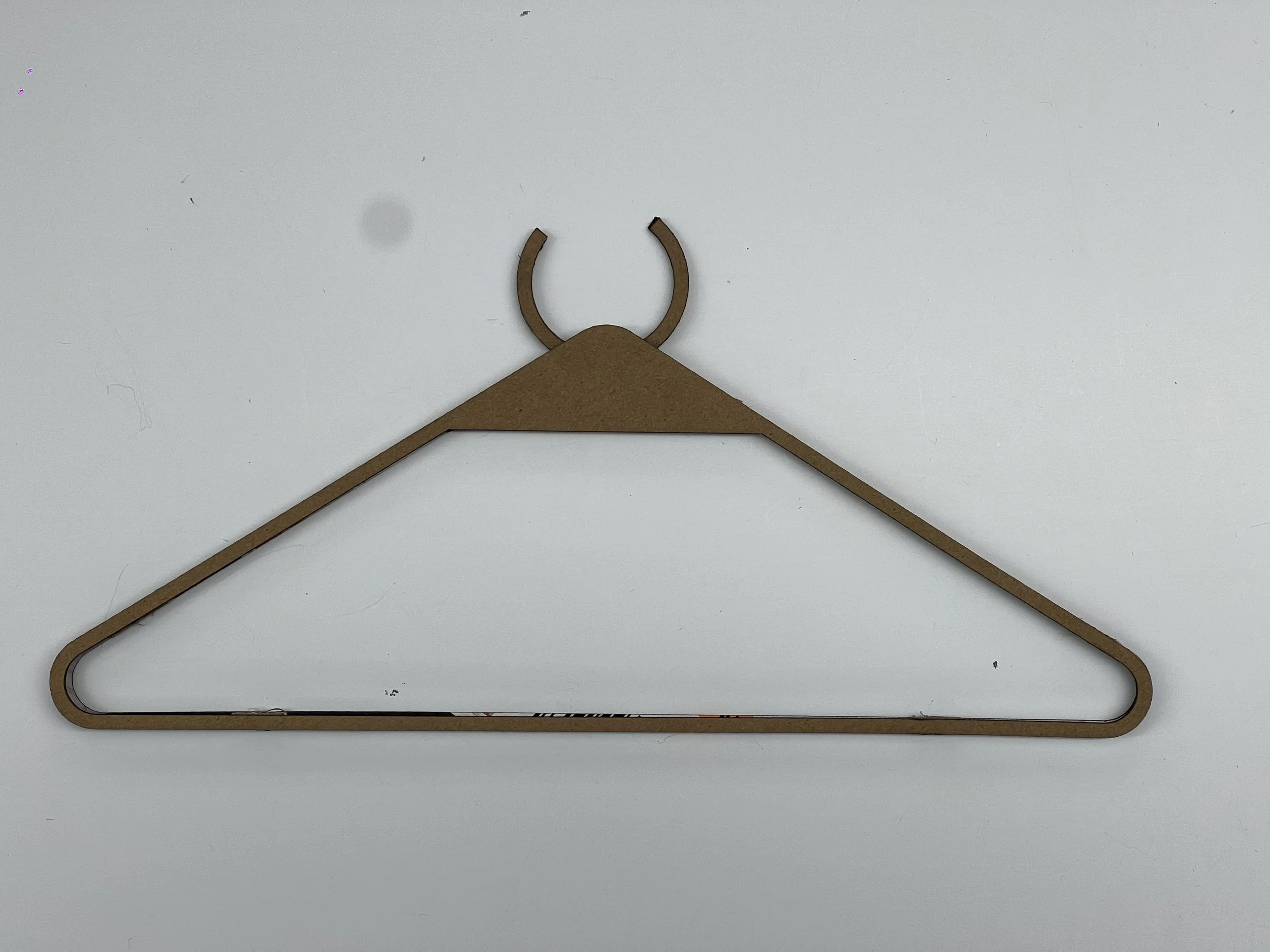

We 3D printed our first pair of gear and hook but were unsatisfied with the result and size. So we adjusted the size and laser cut a new set and a simple housing for prototype purposes.

Side detection with sensors

IMU data with machine learning: https://experiments.withgoogle.com/tiny-motion-trainer We were having an accuracy of about 60%, which is totally not working.

Difference between two IMU: With the help of two accelerometer data, we can calculate the difference between them. The part with a lower rate of acceleration is the side that is held by hand. https://vimeo.com/642191133

CMF

We plan to use white oaks for the frame, semi-transparent white plastic for the housing, and aluminum for the hook. The green color will be used as decoration highlights on the hanger.

TODO

3D print / CNC hook and gear

CNC Wooden hanger frame

3D print housing for gear and electronic

Sanding/Spray/Final touch

Timeline

Finish all parts by 11/8, Monday

Assemble all parts by 11/9, Tuesday

Starting Final touch and finish documentation starting 11/9, Tuesday and finish by the class 11/11